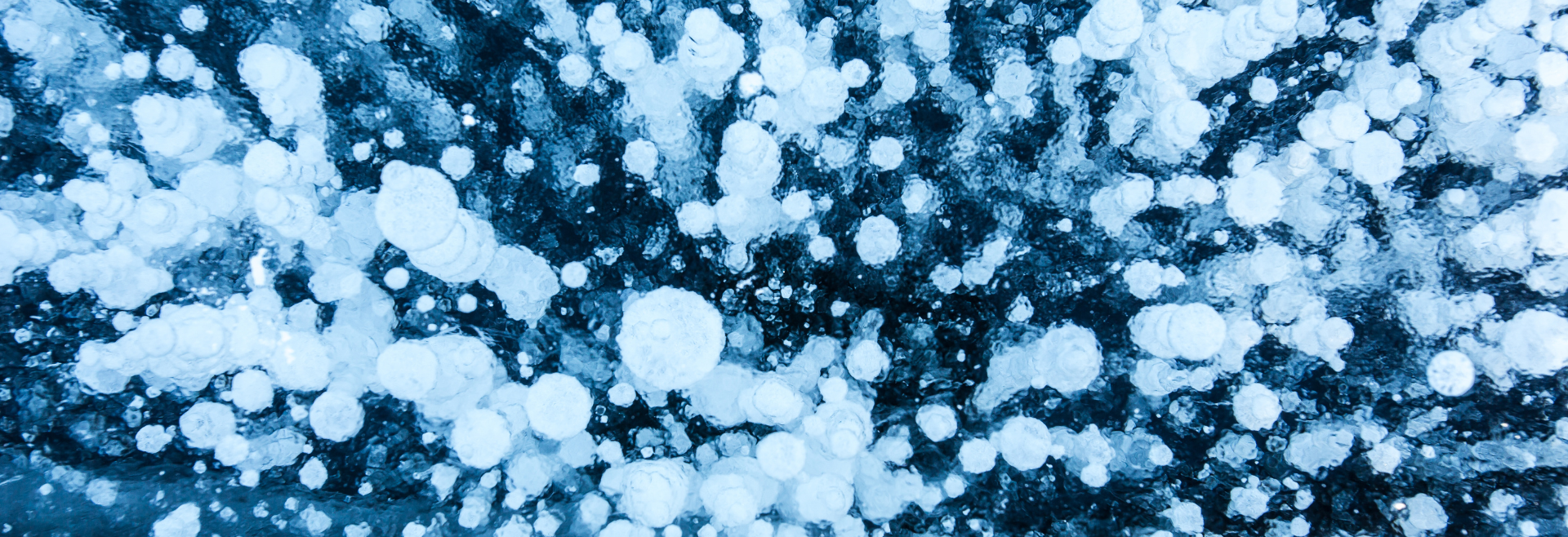

Our client needed to determine whether gas migration is occurring through cement plugs, assess whether it is continuous or intermittent, and evaluate the influence of ambient conditions. Precisely quantify gas migration rates, monitor headspace shut-in pressure, and capture fugitive emissions for compositional analysis.